Servo based motion continues to grow as drive technologies become more affordable and easier for motion control programmers to integrate into projects. Some manufacturers have really reduced the ease of implementing servo devices to be extremely close to that of buying an off the shelf robot: Let the software know that you are using a servo drive, give it a real name, let it know the gearing ratio it may have, and what the output distance of that gearing is and you are set. The software configures the rest and tunes the system automatically, leaving the motion programmer with the task of telling the servo system, in machine units (degrees, millimeters, inches), where you would like it to go and how fast, or in some cases, moving the mechanical load to the position and teaching the system. Even replacing a mechanical cam with an electronic cam is easy. Simply get the polar coordinates of the mechanical cam (really easy with CAD software) and export the coordinates into the servo’s cam generator software.

Topics: servomotor, engineeringdesign, motioncontrol

Industrial Drive Service Inc. is a drive systems integrator business based in Hensall, Ontario. Most of their projects involve a motor, drive and a programmable logic controller. One of their niche markets is hoist controls used in the mining industry. In 1995 they were involved with a hoist installation in Peru. The project went well and resulted in many subsequent hoist projects, the latest being in 2019.

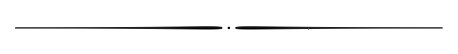

In recent years the way electricity is used has changed significantly. Developments in semi-conductor technology have created a major increase in thyristor and converter-fed loads. Electronic equipment, particularly that using solid state devices, can have a detrimental effect on the electrical power system in a facility to the point where operation of electrical and electronic equipment is disrupted. Solid state devices generate Harmonics into the electrical system, i.e. they generate frequencies that are integer multiples of the fundamental line frequency of 60 Hz. The harmonics lead to a higher capacitor current, because of the higher frequencies that are attracted to the capacitor. The impedance of the capacitor decreases as the frequency increases.

Harmonic distortion can result in any or all of the following:VFDs and their effect on the power factor of a common AC induction motor

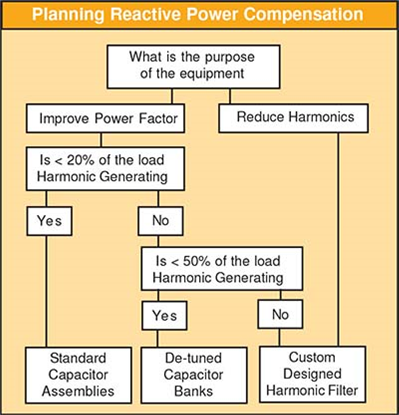

In a common AC induction motor, a magnetic field is induced in the rotor and the power is supplied directly to the stator. The power used to induce the magnetic field in the rotor is commonly known as reactive power since it does not produce work. The power supplied to the stator is best known as active or real power for it produces the torque of the motor. Together, the real and reactive power form the total or apparent power in the system. This is often depicted on a power triangle.

Topics: power factor, power quality, VFDs

Topics: power factor, power factor correction, power capacitors

5 Reasons You Should Be Collecting Production Data Directly from Your Equipment

Industry 4.0 is a term being used a lot in the industrial world right now. It can be applied to anything from batch size 1 machinery to artificial intelligence; essentially technologies we expect to see in a modern-day facility. One of the topics of Industry 4.0 is data collection: How do we get it? Who gets it? What do we do with it?

Topics: data, orange box, kpi, IoT, Industry4.0

VFD Design: How to connect contactor to motor using safety relays

In the early days of variable speed drives, Nema rated motor contactors were used. The more economical IEC rated contactor had not be introduced. As variable speed drive technology improved and sequencing the opening of the contactor to coordinate with the termination of current flow to the motor became reliable, the need for a contactor to break an arc took second place to the use of a contactor for isolation purposes. This meant that the more robust and more expensive Nema contactor was not required.

Topics: VFDs, safety, motorcontactor

What is power factor correction?

Power factor (PF) is a measure of system electrical efficiency. A business that does not manage their PF will likely suffer from financial and operational losses as a result. PF correction is the process of bringing PF closer to 100%, or unity.

Topics: power factor, ROI

VFD Maintenance: Don't Get Caught With Unformed Capacitors!

I recently had a situation occur where a customer had a VFD fail and asked me to set up the spare in its place.

Topics: electrolytic capacitors, VFDs

Industrial Drive Service Cuts Monthly Electricity Bill in Half

IDS employees regularly repair and perform testing on previously failing drives that are loaned to them from other large industries. Testing is completed through a half hour load test on the drive to determine the effectiveness of the repair. The power factor of the main facility at IDS drops to 0.20 and below during the time of load testing.

Topics: power factor, power quality